Nanotech Energy and three other companies are teaming up to introduce recycled metal into lithium-ion battery production.

Lithium-ion batteries are essential components of electric vehicles, and with increasing demand for EVs, demand for these batteries (in terms of overall capacity needed) is projected to increase by 2030 to about seven times the 2022 demand, according to McKinsey. This is clearly a win for the environment, as electric vehicles have drastically reduced pollution footprints compared to conventional passenger vehicles that burn dirty energy sources.

However, lithium-ion batteries have down sides –– the metal used to create them is often mined in destructive ways that produces significant pollution and can hurt local ecosystems. And very few depleted batteries end up recycled, which means that discarded lithium-ion batteries wind up leaking harmful toxins into our environment, according to Freethink.

Fortunately, Nanotech and its partner companies are beginning to use a system that will close the loop on lithium-ion battery production.

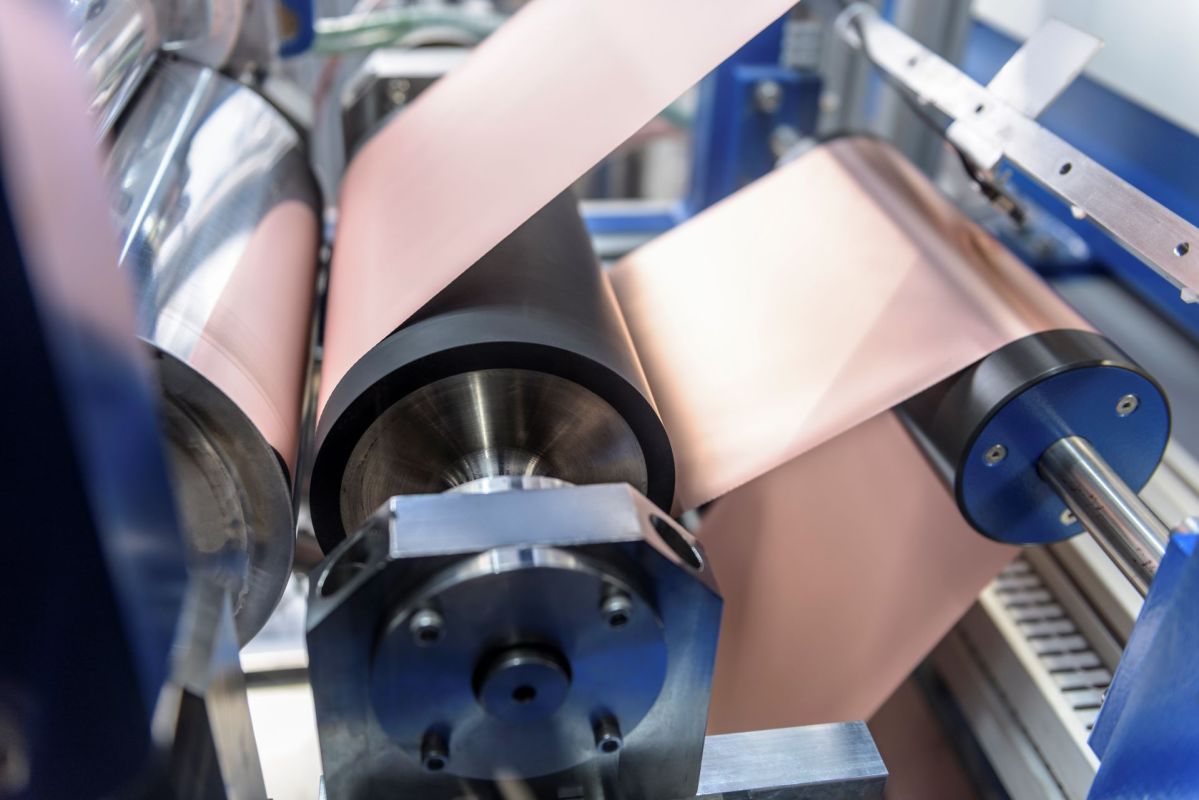

The process, according to Freethink, begins with Nanotech sending lower-quality scrap materials to the American Battery Technology Company (ABTC), which will recycle parts of the scrap into raw metals that can be used in future battery production.

ABTC will then send those metals to BASF, which converts the metals into cathode active materials, and TODA Advanced Materials, which creates precursor materials that will be used later in battery production. With the materials from BASF and TODA, Nanotech produces a new batch of lithium-ion batteries, which will then generate scrap, and the process can restart.

"By working together, our four companies can pool their expertise and drive better and more sustainable outcomes for the entire North American electric vehicle and consumer electronics industries," Curtis Collar, the chief marketing and sales officer at Nanotech, said in a press release.

"Our partnership with Nanotech, ABTC, and TODA marks an important step for BASF's global battery recycling business," Daniel Schönfelder, the senior VP for battery base metals and recycling at BASF, said in the same release. "Now, we are establishing the first closed-loop system in North America. This enables BASF and Nanotech to produce lithium-ion batteries with locally recycled content."

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.