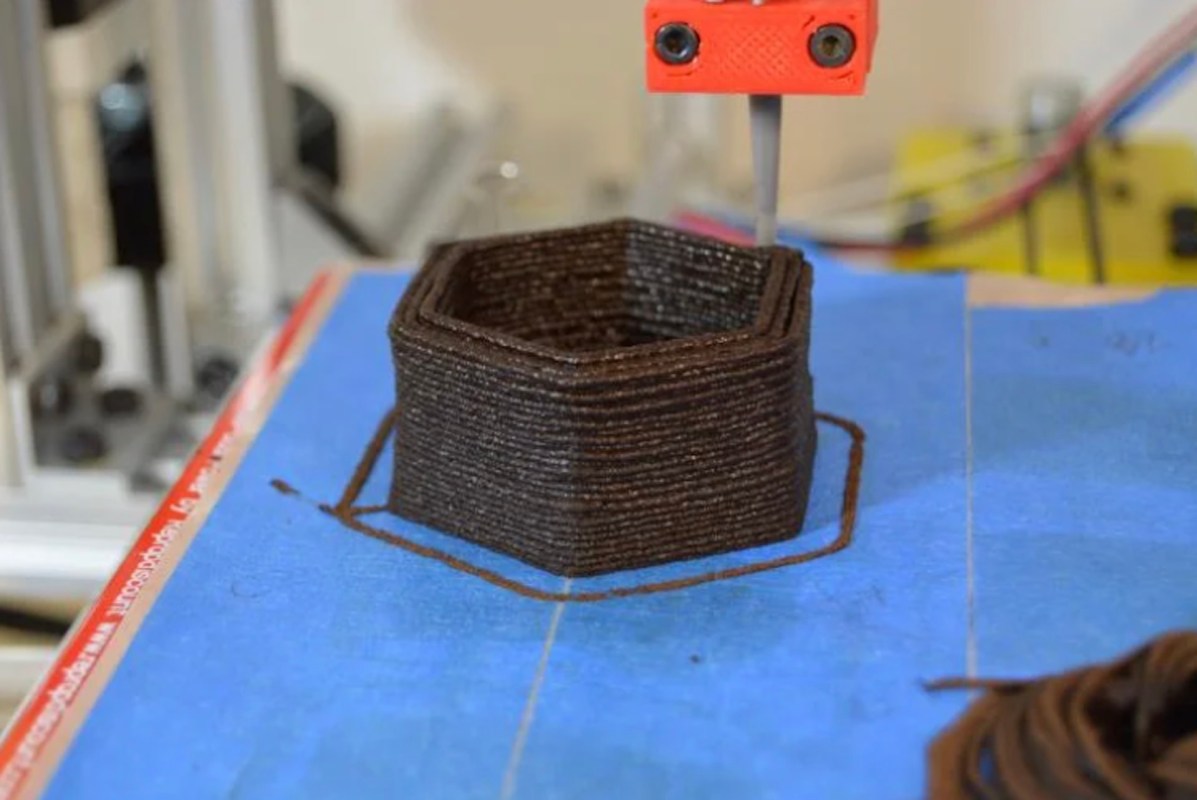

It turns out there's another reason to reach for your morning cup (or two) of coffee. New research from the University of Colorado has found that coffee grounds can be repurposed into items like plant pots and single-use espresso cups with the help of 3D printing technology.

According to Ben Coxworth of New Atlas, assistant professor of computer science Michael Rivera and some colleagues mixed powdered cellulose, xanthan gums, and water with the coffee grounds to make a compostable, food-safe paste that could be fed into various molds.

Because the paste is biodegradable, the plant pots made from the substance can be left in the ground. The material can be recycled as well. If one of the 3D-printed products is no longer useful, it can be turned back into powder and used to create another object.

"You can make a lot of things with coffee grounds," Rivera said, per Daniel Strain and Nicholas Goda of CU Boulder Today. "And when you don't want it anymore, you can throw it back into a coffee grinder and use the grounds to print again."

The findings were published in the journal "Proceedings of the 2023 ACM Designing Interactive Systems Conference."

Rivera and Co. aren't the only ones to find innovative new ways to utilize coffee grounds, with a sneaker company and researchers in Australia among those who've also taken the leap.

The University of Colorado study, however, appears to be the first to combine the common household waste product with 3D printing, which has been growing in its applications since the first printer was invented in 1981.

This marriage of technology and food waste could also be good for the planet on more than one level.

First, as noted in the study, it could help reduce the amount of energy and waste associated with certain types of 3D printing, including by providing an alternative to plastics, which can release harmful toxins into the environment.

Secondly, when they have the chance to decompose in landfills, coffee grounds release methane, a heat-trapping gas that negatively affects the warming of our planet at a rate 80 times stronger than carbon dioxide.

Rivera, who got inspiration for his research when he saw coffee-ground waste accumulating during the COVID-19 pandemic, hopes his technology is able to help make 3D printing more sustainable across a range of industries.

"If you throw [polylactic acid (PLA)] in a landfill, which is where the majority of PLA ends up, it will take up to 1,000 years to decompose," said Rivera, referencing a material currently used in most 3D printing, per CU Boulder Today.

"Our vision is that you could just pick up a few things at a supermarket and online and get going," Rivera added.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.