Florida construction materials manufacturer Miami Echo has discovered an incredible new way to recycle old tires, including the ones it will pull from the failed Osborne Reef.

Nine years ago, Miami Echo founder Richard Spreen read about Osborne Reef in a local paper.

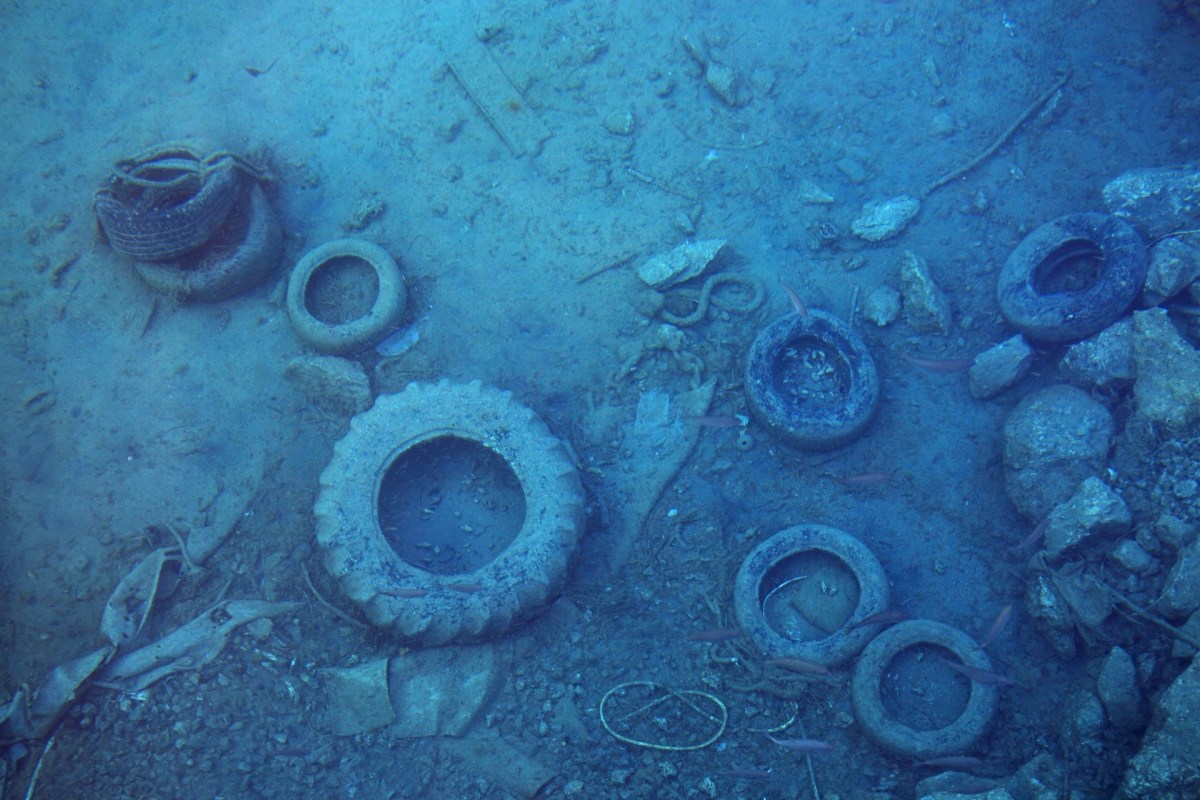

The 50-year-old project was a failed attempt to make the world's longest artificial reef from used tires. Instead of growing coral, however, the two million tires broke apart, polluting the ocean in the area and damaging existing coral as the waves battered them into the surrounding reef.

Today, over 500,000 tires from the project remain in the ocean.

Spreen decided there was a better way to use old tires. Drawing on experience in construction and roofing, he created Echo Flow, a unique building material that uses pieces of discarded tires as a main ingredient. He then went through a multi-year process to set up his manufacturing facility and have the material tested for use in buildings.

"You wake up every morning with something in front of you that's impossible," Spreen told The Cool Down. "It's exciting every day because we're building something that's never been built before."

To create Echo Flow, Miami Echo shreds tires into small pieces, combines them with a proprietary cement blend, and shapes them into strong but porous bricks that water can flow through freely.

Echo Flow became the basis for a rooftop system like no other: Echo Terrace. The top layer is made of permeable Echo Flow bricks, while the bottom layer is made of Echo Blocks — the same material, but topped with a solid barrier.

When water hits the rooftop, it flows through the Echo Flow bricks until it hits the barrier. The slope of the Block bricks guides the water toward a drain, while the counter-slope of the Flow bricks ensures the top surface of the roofing system stays completely level.

Echo Terrace's ability to absorb rainwater creates opportunities for beautiful and unique rooftop designs. Miami Echo shared images of an ongoing project at NEXO Residences in Miami, which will incorporate a rooftop pool, seating areas, an outdoor theater, and lush greenery featuring full-sized palm trees.

"You know who else can do that work?" Spreen asked. "Nobody. And nobody ever probably will."

Besides letting water through to keep the surface dry, Echo Terrace offers a number of other benefits for contractors and building owners. For one thing, the system slows stormwater down to make it easier for drainage systems to handle. A wide range of surface materials can be laid on an Echo Terrace foundation, including Astroturf, tile, and ironwood.

The material has been thoroughly tested to Miami-Dade County's highest standards and completed its certification with 100% approval in 2022. Spreen said it has a two-hour fire rating, gets about 30% stronger with age instead of getting weaker, and can even be used to construct hurricane-rated shelters.

The building material is also eco-friendly.

"It's a 93% certified recycled content product," Spreen said.

That includes the cement, as Miami Echo's proprietary cement formula is much less polluting than the industry-standard Portland cement. It's made from recycled waste products like silica fume (from making silica) and cement slag (from processing iron ore).

Echo material is also recyclable. At the end of its lifespan, an Echo brick can be broken down in a rock crusher and used to make new bricks, according to a company representative.

Miami Echo is committed to eco-friendly construction. Another upcoming Echo Terrace project at the Royal Caribbean World Headquarters will include a rooftop soccer field. To complete it, Miami Echo plans to pull 30,000 discarded tires from Osborne Reef this year.

Join our free newsletter for cool news and actionable info that makes it easy to help yourself while helping the planet.