Government battery experts may have found a way to remove a slurry of toxic solvents typically needed in the process to make battery electrodes. They are developing a dry technique in partnership with Navitas Systems, a battery tech company from Michigan.

If the experts from the U.S. Energy Department's Oak Ridge National Laboratory and Navitas are successful, the innovation could expand the EV market, researchers said in an article on the lab's website.

What's more, the dry method could reduce air pollution and help the country meet its climate goals, which include a "net-zero emissions economy by 2050."

The main issue is the wet process that battery electrodes are commonly made through, which the Oak Ridge scientists said carries environmental and health risks because of the excess of toxic solvents used.

"Dry processing can eliminate the coating and solvent equipment currently necessary for large-scale battery production," Navitas researcher Bryan Steinhoff said in the report.

The thicker electrodes made with the dry process held up "superbly" during testing, even during long use, experts said. They allowed the lithium ions, which create energy as they pass back and forth between electrodes, to travel on a more direct path. This eliminates "inactive ingredients," making the tech smaller and lighter, maximizing the space, all according to the Oak Ridge research report.

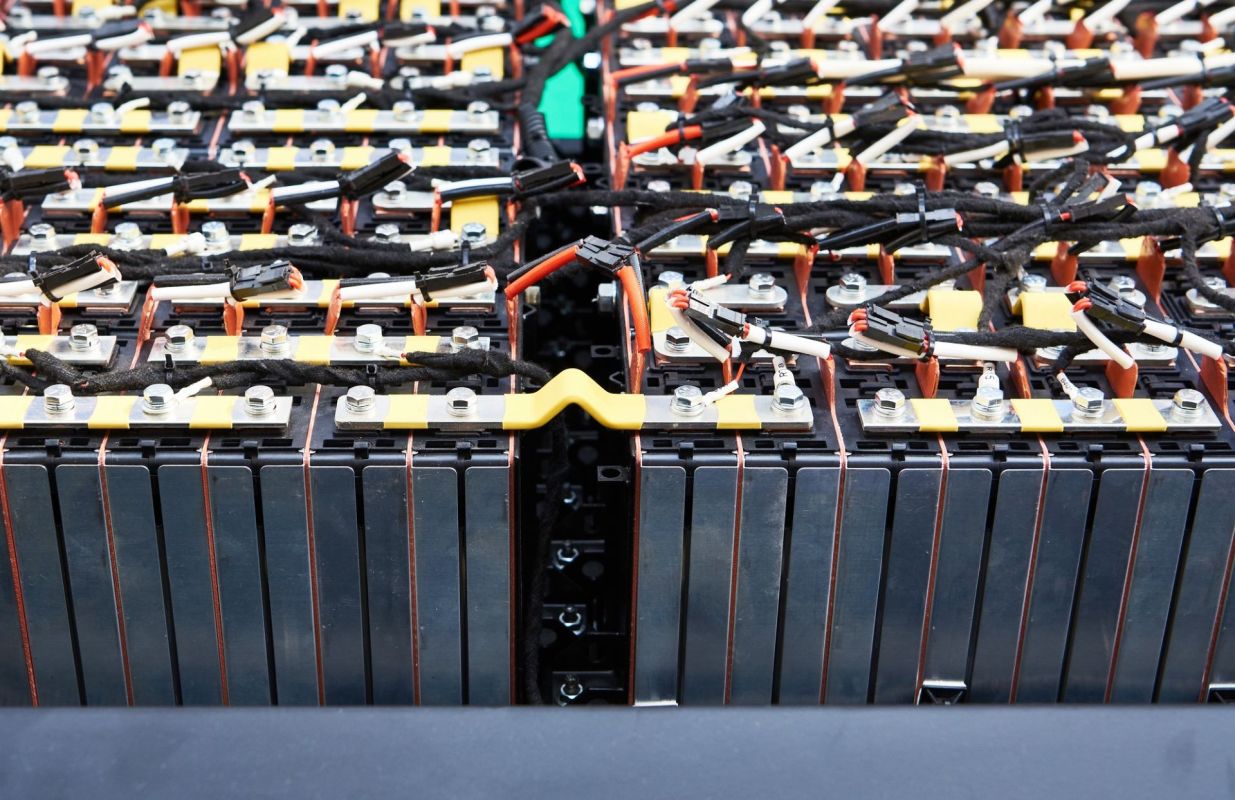

A photo of the product looks like a wide strip of duct tape. The electrode film, made by Navitas, is strong and flexible.

"There are more active materials in the electrode," Oak Ridge lead researcher Runming Tao said. "And even after cycling, it will have few cracks."

The test proved flexibility and mechanical strength, traits needed for mass production. Now, the concept must be proved further before being rolled out to battery plants. There, researchers said the dry method will save space, among all the other benefits.

A key remaining task is making sure the electrode parts attach securely during the dry method.

"A main goal for this project is to develop or identify a better binder for the dry process, because the current binder is not very stable for the anode environment," Jianlin Li, another lead researcher, said.

Once the electromechanical tweaking is complete and the dry process proves efficient, it could be the main method in factories, creating electric power options more cleanly.

"If you can use a dry process instead, you can reduce your footprint by up to 40% or 50%, saving hundreds of millions of dollars and starting to enable the creation of an infrastructure to replace one that is largely dependent on Asia at the moment," Steinhoff said in the report.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.