Sodium just gained some ground in the race to replace lithium as the crucial material in batteries.

That's because experts at Osaka Metropolitan University in Japan announced a key process to make salt-based batteries, potentially opening the door for mass production.

At issue is costly and hard-to-gather lithium, the reliable, incumbent battery metal that helps to power electric vehicles and most other tech. More common materials are being developed as substitutes for power pack chemistry in labs around the world. The innovations are part of efforts that could lower the cost of EVs, helping to increase market share for the cleaner rides.

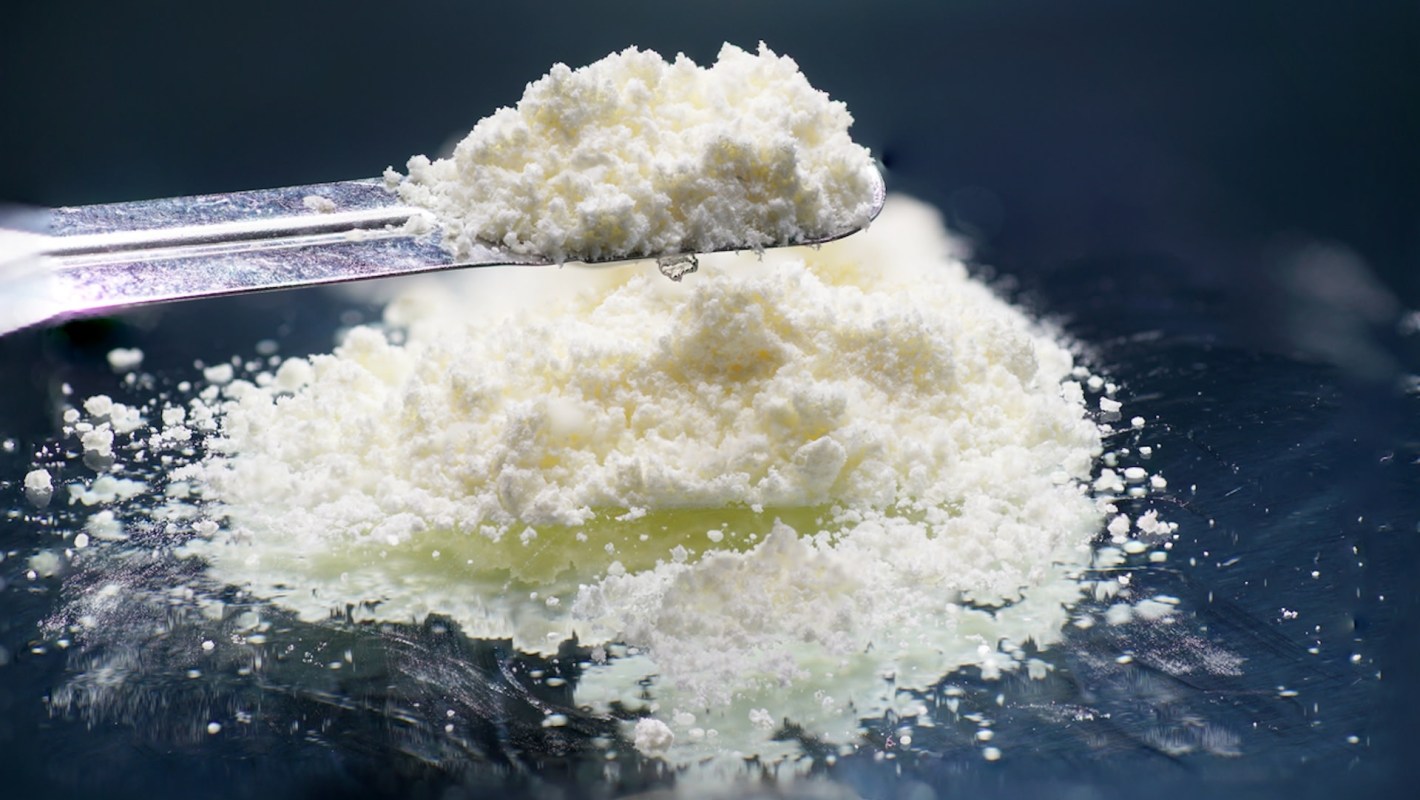

The Osaka team says it developed advanced chemistry to produce a "solid sulfide electrolyte with the world's highest reported sodium ion conductivity — about 10 times higher than required for practical use." The breakthrough also includes a glass electrolyte with high reduction resistance.

The experts consider the conductivity benchmark to be vital for the sodium concept to work and make salt usable for key battery parts.

"This newly developed process is useful for the production of almost all sodium-containing sulfide materials, including solid electrolytes and electrode active materials," associate professor Atsushi Sakuda said in a lab summary.

In lithium batteries, ions travel between the anode and cathode (electrodes) through a material called electrolyte. Electrolyte can be a solid or a liquid, though many experts consider the former to hold greater potential and to be safer.

The Osaka innovation takes advantage of both cheaper, abundant sodium and safer, more energy-dense solid electrolyte.

It could be a great combination for the EV market, evidenced by the fact that growing juggernaut BYD is investing in sodium power packs.

In the United States, EV sales growth has slowed, according to Cox Automotive. But the data collector still predicts 2024 to be a banner year for the sector. In fact, Cox forecasts this to be the best year ever for EVs.

"Analysts expect EV sales to reach roughly 10% of the market by the end of the year, up from 7.3% in the first quarter," per a summary from the firm.

Every EV that replaces a gas guzzler represents cost savings, fresher air, and better health for people and the planet. EVs prevent up to 10,000 pounds of harmful dirty air from hitting the atmosphere each year. Up to $1,500 a year can be saved on gas and maintenance costs, as well.

Osaka's salty announcement could spice things up a bit, as the research team touts that sodium batteries are now closer to practical use.

"Compared to conventional methods, this process makes it easier to obtain materials that display higher performance, so we believe it will become a mainstream process for the future development of materials for all-solid-state sodium batteries," Sakuda said in the report.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.