Silicon is considered by many battery experts to be superior to graphite as an anode material in electric vehicle batteries.

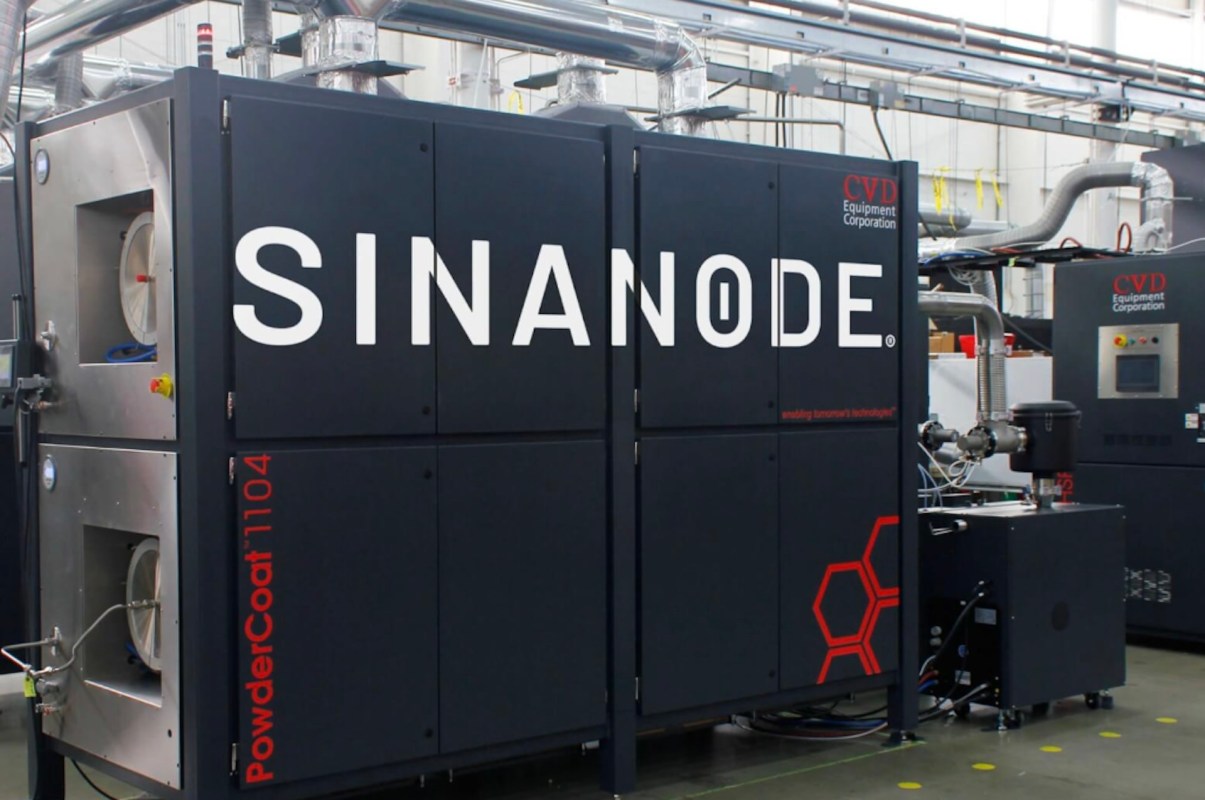

But California's OneD is instead using silicon to enhance graphite, producing the supercharged Sinanode that is promoted by the company to increase performance while lowering costs.

That means, according to Reuters, more range and shorter charge times for motorists. It's good news for anyone considering an EV in coming years, as the tech continues to become more efficient, cheaper, and better performing.

Now, OneD is partnering with New Jersey's Koch Modular to build a facility in North America — worth a "few hundred million dollars," per Reuters — to ramp up anode production for a million EV batteries each year.

"Together, we are excited to help scale up silicon-enhanced graphite production and help each customer achieve a more competitive global market position by combining our proven technology platforms," Koch President George Schlowsky said in a report from AZoCleantech.

OneD's silicon innovation is different from others because it uses both silicon and graphite. The latter material commonly forms battery anodes, though it is subject to foreign supply chains. Reuters reports that China processes 90% of the planet's graphite. The Chinese government recently rolled out graphite export rules, causing worry among industry leaders around the world about the material's availability. It's an example of why officials in the West want to strengthen regional supply chains.

In most EV batteries, lithium ions travel between the anode and cathode during the charge/discharge process. Silicon is touted as a better material, holding 10 times more power than graphite, per OneD.

By working with graphite, instead of supplanting it entirely, OneD's team claims to be able to leverage existing supply chains for graphite without disrupting manufacturing processes.

During production, OneD infuses silicon nanowires in the graphite. It said on its company website that this "supercharges" the material. The nanowires fill internal graphite pores, making the silicon ready for lithium ions, a needed condition for the battery chemistry to work.

What's more, it nullifies silicon expansion, one of the sticking points to the technology to date. The end result is an anode that is a versatile, smaller electrode with the ability to store more energy than one made with graphite alone. Better yet, the cost is lower overall, per OneD.

Silane gas is needed to make a Sinanode. That's where Koch enters the process. A Koch silane plant will purify the silicon before it heads to OneD's facility, where it will be introduced to graphite, Reuters reported.

Business Wire noted that a Sinanode pilot production plant is set to go online early this year in Moses Lake, Washington. In the meantime, large-scale production plants are being completed, per the report.

"This strategic collaboration will enable the North American EV battery supply chain to reduce its dependency on overseas anode material imports," OneD CEO Vincent Pluvinage said in the Business Wire report.

Join our free newsletter for weekly updates on the coolest innovations improving our lives and saving our planet.